Sider REFRACTORIES

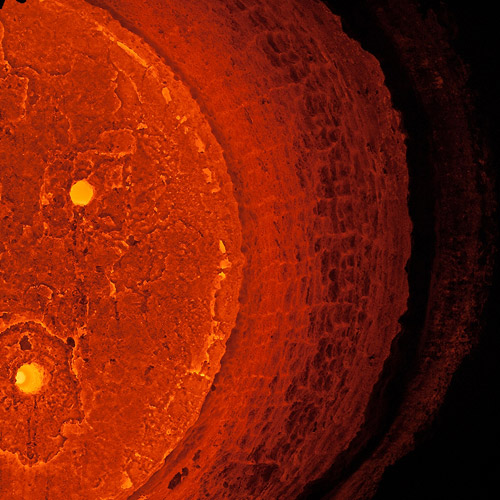

LADLE

FURNACE

Steel casting ladles and ceramics

for the steel industry

Steel casting ladles have evolved during the years from pure transport vessels into a metallurgical reactor for modern steel production.

This brought increasing demands on the linings. Nowadays, many customers prefer ladles that are mainly lined with high-grade fused magnesite bricks. Our customers require personalized solutions, in order to optimize the consumptions on the basis of their operations and metallurgical requirements. We provide detailed solutions, from basic construction steel grades, up to special and stainless steel.

We also provide functional ceramics associated with steel casting ladles, such as purging and slide gate systems, including well blocks, nozzles and slide gate plates.

FUNCTIONAL CERAMICS

WELL BLOCKS AND NOZZLE: Manufactured in our workshops in Italy, our products are made with European high performance refractory castables and are characterized by high density / low porosity and high strength.

PURGING PLUGS: SID-PLUG purging plugs can be provided in different models, non-directional (porous), directional or dynamic.

PLATES: SID-PLATES Slide Gate Plates provide a high corrosion resistance and improved thermal shock resistance. For our Sider Gate systems, we have also optimized refractory plate design for plate crack control and finite element studies to predict thermo-mechanical behaviour. Produced with the latest technologies are finished in our workshops in Italy, which guarantees a clear quality control and assures optimal results to our customers.

BRICKS

WALL AND BOTTOM: SID-MAG bricks made with a blend of fused and sintered Magnesia; by request also with low residual Carbon content.

SLAG ZONE: SID-MAG made of high grade fused Magnesia with increased residual carbon content.

IMPACT AREA: Bricks made of Allumina-MgO-Carbon with increased erosion resistance.

PERMANENT LINING: Bricks made of calcined bauxite or andalusite quality.

|

Quality |

MgO |

Al2O3 |

Fe2O3 |

C |

B.D. |

A.P. |

CCS |

||

|

% |

% |

% |

% |

Kg/m3 |

Vol. % |

Mpa |

|||

|

Sid-Mag 7FN |

96 |

0,8 |

0,8 |

7 |

3,01 |

11 |

33 |

BARREL AND BOTTOM |

WORKING LINING |

|

Sid-Mag 10FN |

95,3 |

1,2 |

0,8 |

10 |

2,96 |

11,4 |

30 |

||

|

Sid-Mag 7EN |

96,2 |

0,7 |

0,7 |

7 |

3,06 |

10,6 |

35 |

||

|

Sid-Mag 10EN |

95,8 |

0,9 |

0,7 |

20 |

3,01 |

10,8 |

33 |

||

|

Sid-Mag 14CN |

96,9 |

0,2 |

0,6 |

14 |

3,01 |

10,6 |

34 |

TRANSITION AND SLAG LINE |

|

|

Sid-Mag 12CN |

96,9 |

0,2 |

0,6 |

12 |

3,03 |

10,4 |

35 |

||

|

Sid-Mag 7CN |

96,9 |

0,2 |

0,6 |

7 |

3,1 |

10,2 |

36 |

||

|

Sid-Mag 14BN |

97,4 |

0,1 |

0,5 |

14 |

3,04 |

10,3 |

36 |

SLAG LINE AND HOT SPOT |

|

|

Sid-Mag 12BN |

97 |

0,1 |

0,5 |

12 |

3,07 |

10,1 |

37 |

||

|

Sid-Mag 15U |

98,2 |

0,1 |

0,4 |

15 |

3,03 |

9 |

40 |

|

Quality |

MgO |

Al2O3 |

Fe2O3 |

C |

B.D. |

A.P. |

CCS |

||

|

% |

% |

% |

% |

Kg/m3 |

Vol. % |

Mpa |

|||

|

Sid-MAC 6K |

91,2 |

5,9 |

0,7 |

12 |

3,1 |

10 |

40 |

SPINEL MATERIALS |

|

|

Sid-SMAC 6M8MP |

8,2 |

87,2 |

0,2 |

8 |

3,27 |

10 |

42 |

||

|

Quality |

MgO |

Al2O3 |

Fe2O3 |

C |

B.D. |

A.P. |

CCS |

||

|

% |

% |

% |

% |

Kg/m3 |

Vol. % |

Mpa |

|||

|

Sid-Mag 12C |

97 |

0,2 |

0,6 |

11 |

2,95 |

5,8 |

32 |

FUME LESS |

|

|

Quality |

MgO |

Al2O3 |

Fe2O3 |

Grain size |

|||

|

% |

% |

% |

mm |

||||

|

Sider Fill |

76,5 |

0,8 |

7,5 |

0-2 |

BACKFILL |

MgO base |

|

|

Quality |

CaO |

Al2O3 |

Fe2O3 |

Grain size |

|||

|

% |

% |

% |

mm |

||||

|

Sid-cast k97 |

4,2 |

95 |

0,1 |

0-6 |

DENSE REFRACTORY |

ALUMINA BASE |

|

|

Sid-cast K80 |

2,4 |

80 |

0,8 |

0-6 |

VIBRATABLE REFRACTORY |

||

|

Quality |

Cr2O3 |

Al2O3 |

Fe2O3 |

Grain size |

|||

|

% |

% |

% |

mm |

||||

|

Sid-cast Cr95 |

3 |

88 |

0,5 |

0-0,2 |

REFRACTORY MORTAR |

ALUMINA BASE |

|

|

Sid-cast Cr-S |

5 |

86 |

0,2 |

0,5 max |

|||

![]() DOWNLOAD THE TABLE

DOWNLOAD THE TABLE

CONNECT WITH US FOR SUPPORT OR ANY QUESTION!

CONTACT FORM

+39 030 7002350

SUPPORT

for our Customers